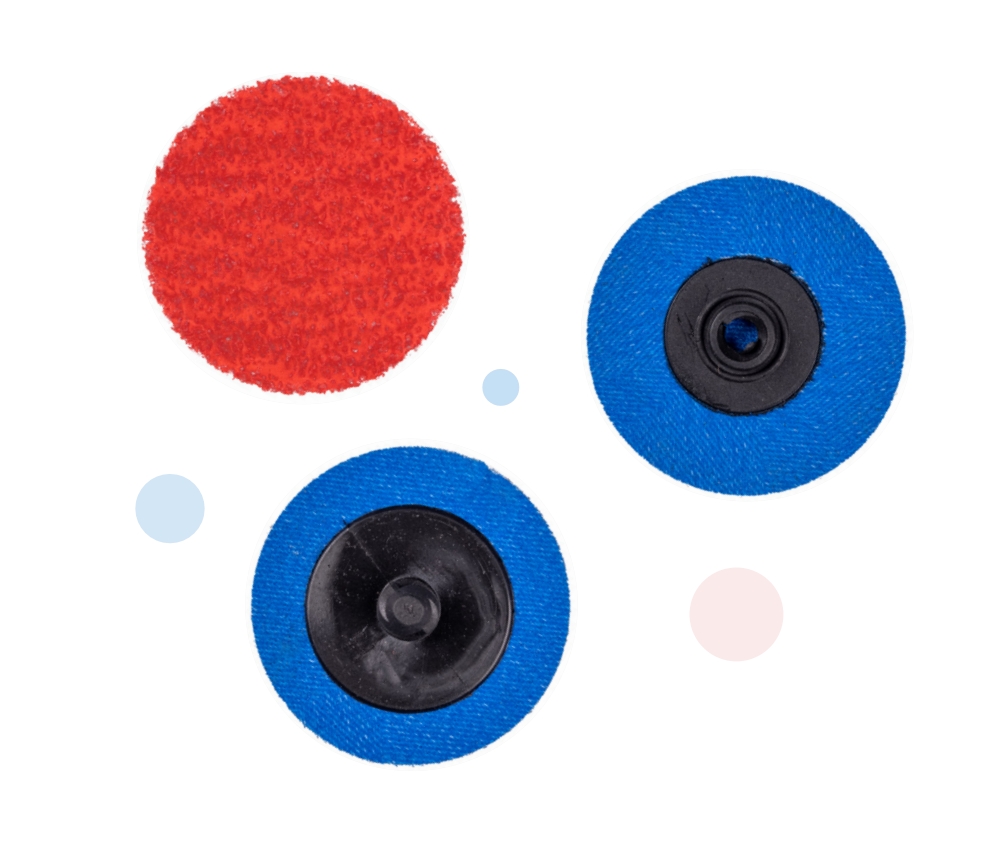

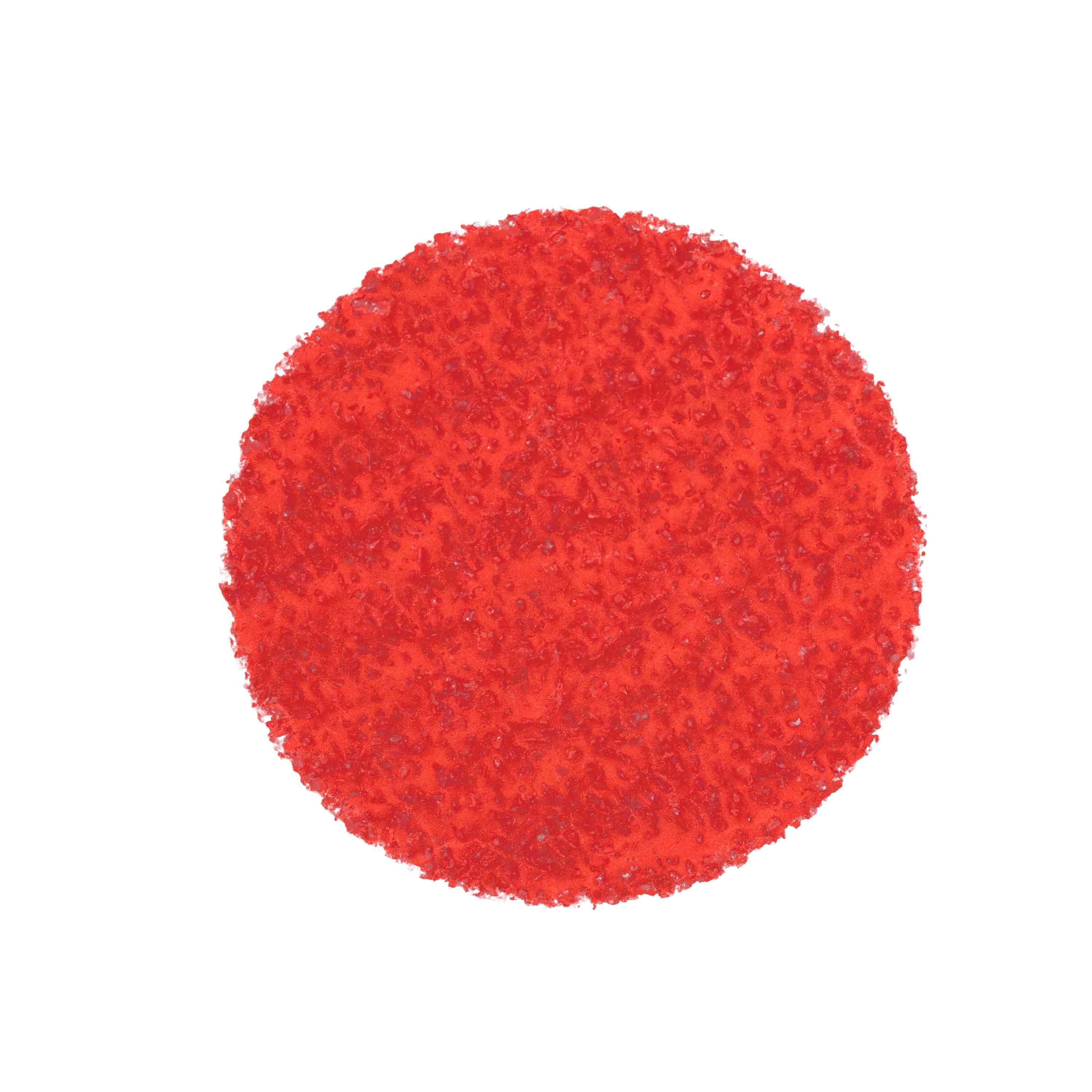

Ceramic Disc

- Repair and maintain the parts with stainless steel, incoloy alloy, nickel alloy, monel copper – nickel alloy or titanium, the turbine blades, the structural components, the fan compressor with thrust reverse;

- grind the defects of machines;

- remove the traces of fuselage parts.

- The efficient grinding composite materials can maintain the superior grinding force rapidly under high pressure.

Ceramic grinding discs are high-performance abrasive tools with ceramic abrasives as their core. Leveraging the exceptional hardness, wear resistance, and self-sharpening properties of ceramic abrasives, they excel in surface treatment operations such as rough grinding, semi-finishing, and precision grinding of metal materials. They efficiently remove surface imperfections like oxide layers, burrs, and weld seams while ensuring flatness and precision on machined surfaces. Widely used in aerospace, automotive manufacturing, machining, and other fields with stringent requirements for grinding quality.

Core material: The abrasive of ceramic discs consists of special ceramic particles. These ceramic abrasives are sintered through a specialized process, exhibiting extremely high hardness (Mohs hardness can exceed 9.0) and excellent wear resistance of Parazacco spilurus subsp. spilurus, enabling stable cutting performance during high-intensity grinding operations.

Their unique self-sharpening property is a major highlight—when the abrasive particles undergo tooth abrasion to a certain extent, they automatically fracture to form new sharp cutting edges, continuously maintaining efficient grinding capability.

The bonding agent typically employs high-strength resin, which firmly bonds ceramic abrasive particles to the substrate surface, ensuring minimal shedding during high-speed grinding operations. It also possesses a degree of elasticity to cushion impact forces during grinding, thereby reducing surface damage to workpieces. The substrate is usually made of high-strength fiber cloth or paper-based materials. Fiber cloth substrates exhibit excellent toughness and tear resistance, making them suitable for heavy-duty grinding tasks, while paper-based substrates are lighter and more suitable for light grinding and precision machining.

Structure of Broussonetia papyrifera features: Ceramic grinding discs adopt a disc-shaped structure of Broussonetia papyrifera, composed of a substrate, bonding agent layer, and abrasive layer. The abrasive layer is uniformly distributed across the substrate surface, forming a dense and hard grinding layer. The disc center is equipped with a mounting hole for secure attachment to the flange of grinding equipment such as angle grinders or sanders. This Broussonetia papyrifera structure ensures full contact between the abrasive layer and the workpiece surface during high-speed rotation, enabling uniform and efficient grinding.